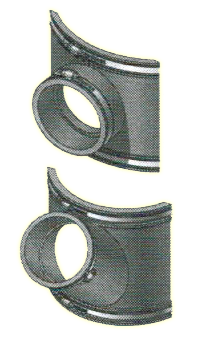

Saddle T's and Y's

For superior durability and flexibility, saddle up.

A breakthrough in saddle design, the patented Rollee Flexible Saddle demonstrates superior flexibilty in more than one way. The saddle`s elastrometric construction allows a single description to securely fit 6" sewer main pipe diameters and up. The saddle`s flexibility eliminates the need for a large inventory of rigid PVC saddles of various descriptions.

A breakthrough in saddle design, the patented Rollee Flexible Saddle demonstrates superior flexibilty in more than one way. The saddle`s elastrometric construction allows a single description to securely fit 6" sewer main pipe diameters and up. The saddle`s flexibility eliminates the need for a large inventory of rigid PVC saddles of various descriptions.

Flexible Saddle offers the following product benefits:

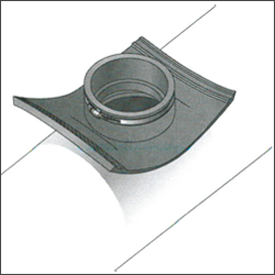

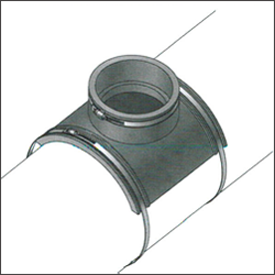

- Two configurations, a "Tee" and a "Wye" are available in 4" or 6" inlet descriptions

- Esometric construction provides maximum strength and flexibility

- Saddle design will accomodate polyethylene pipe used in slip lining sewer systemms

- Inlet range from SCH-40 down to SDR-35 includes standard weight soil pipe

- Stainless steel series 300 clamps ensure tight seal

- Steel reinforced edges prevent distorion when torque is applied to clamps

- Durable design and low unit price make the Flexible Saddle economical and environmentally wise

- Available Saddle Blanket, attached to pupe prior to saddle installation, will mend imperfections and cracks on clay pipe taps

Flexible Saddles

|

Part No. | Description | Color | PKG QTY |

|---|---|---|---|---|

| 4-RST | 4" Saddle Tee | Black | 12 | |

| 4-RSY | 4" Saddle Wye | Black | 12 | |

| 6-RST | 6" Saddle Tee | Black | 6 | |

| 6-RSY | 6" Saddle Wye | Black | 6 |

{slider ASTM Material Specification|closed}

| Test | Material | ASTM Test mateial |

|---|---|---|

Chemical Resistance

|

No weigh loss |

D543 |

| Tensile Strength Elongation | 1000 psi (7/Mpa) min, 200% min. elongation at break | D412 Dle "C" |

| Duration Hardness | Shore Durometer 50 min to 75 max | D2240 |

| Compression Set | 90% max of original deflection | D395, Method B Type 2 |

| Water Absorbsion | 5% max | D471 , immersed 7 days @ 158 Method A |

| Ozone Resistance | No visible cracking under 7x magnification | D1149, D518 Method A |

| Oven Aging |

75% min of original tensile strength |

D573 (158° F for 70 hours) |

| Cold Brittleness | Cold Brittleness was determined to be -43°C | D476 |

| Tear Strength | 125 lbs / in | D624 Die "C" |

{slider Installation Instructions}

|

STEP 1: |

STEP 2: |

STEP 3: |

STEP 4: Tighten clamps to a minimum of 60 inchj-Lbs (5ft-Lbs torque). |

{/sliders}